Secondary Containment

Secure your operations with GEI Works’ comprehensive Secondary Containment Solutions, including Aluminum Angle Berms, Mini Basins, Foam Wall Berms, Drive-Thru Berms, Absorbent Products, Liquid Storage Solutions, and more. Our durable and reliable products are designed to prevent spills and leaks, ensuring environmental protection and regulatory compliance for a wide range of industrial and commercial applications.

Contain. Control. Collect.

ALUMINUM ANGLE BERM

Crafted using high-quality aluminum, Aluminum Angle Berms are built to withstand demanding environments and effectively contain spills, leaks, and hazardous materials. Its robust construction ensures long-lasting reliability and resistance to corrosion, making it suitable for a wide range of applications.

The Aluminum Angle Berm features a unique design that incorporates sturdy aluminum angles and industrial fabric, providing structural support and stability. This allows for easy setup and ensures the berm maintains its shape, even under challenging conditions.

Installation is quick and easy, thanks to the lightweight nature of the aluminum material. With its portable design, the berm can be easily transported and deployed as needed, making it an ideal choice for emergency response situations and temporary spill containment requirements. It is important to protect the berm from the ground surface as well as the interior. GEI Works recommends using an abrasion pad, liners or drive-tracks depending on your application.

Spill Containment Berm Fabrics and Compatibility

Most of our fabrics are compatible with the following liquids. Please contact our team with MSDS information to confirm compatibility for your specific needs.

- Fuel

- Oil and Grease

- Hydrocarbons

- Chemicals and Small Equipment

- Easy to Set Up

- Folds Up for Storage and Transport

- Easy Drive-In/Drive-Out Options

- Cost-Effective Containment

- Effectively Contains up to 110% of Spilled Liquids

- Reliable Angle Exterior

- Optional abrasion pads, liners, drive tracks and self-bailers available

- Tank Containment

- Fuel Tank Storage

- Frac Tank Spill Containment

- Valve and Leak Control

- Tote Spill Containment

- Spill Response

- Machinery or Fueling Stations

FOAM WALL BERMS

All spill containment barriers are designed as portable containment options that can be moved and transported around one site or from site to site. Multiple sizes and fabrics are available to accommodate different liquids and storage requirements. It is important to protect the berm from the ground surface as well as the interior. GEI Works recommends using an abrasion pad, liners or drive-tracks depending on your application.

Containment Berm Fabrics and Compatibility

Most of our fabrics are compatible with the following liquids. Please contact our team with MSDS information to confirm compatibility for your specific needs.

- Fuel

- Oil and Grease

- Hydrocarbons

- Chemicals and Small Equipment

- Drive Through Ready

- Durable

- Low Profile

- Materials Quickly Moved on and off

- Resists a Broad Spectrum of Chemicals

- Rolls up for Easy Transportation

- Built to your Size Requirements

- Cost-Effective Containment Solutions

- Rapid Response to Leaks and Spills

- Optional abrasion pads, liners, drive tracks and self-bailers available

- Job site Secondary Containment

- Frac Tank Containment

- Car/Vehicle Wash Down

- Leaking Equipment

- Frac operations

- Fueling Trucks/Stations

- HAZMAT Spill Response

- Large Machinery

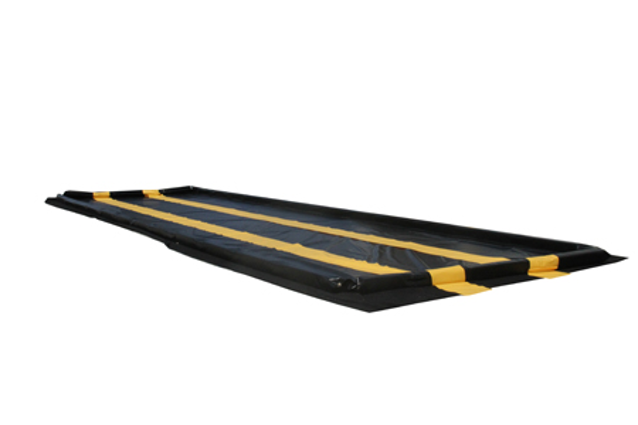

DRIVE THROUGH BERM

Drive Through Berms feature a user-friendly design that allows vehicles to easily drive in and out of the containment area. With its integrated drive-through capability, it eliminates the need for time-consuming manual handling and ensures seamless access for trucks, machinery, and other vehicles. Self-rising foam wall ends remain low in profile until the containment berm starts to fill with liquid, or are pre-formed foam ends depending on style selected.

Installation is quick and hassle-free, thanks to the berm’s flexible and collapsible design. It can be easily deployed and repositioned as needed, making it an ideal choice for temporary containment requirements or emergency response situations.

Versatility is a key feature of the Drive Through Berm. It is available in various sizes and configurations to accommodate different spill containment needs. Whether you require a small-scale containment solution or a larger area for storing drums or equipment, our berm can be customized to meet your specific requirements. It is important to protect the berm from the ground surface as well as the interior. GEI Works recommends using an abrasion pad, liners or drive-tracks depending on your application.

Spill Containment Berm Fabrics and Compatibility

Most of our fabrics are compatible with the following liquids. Please contact our team with MSDS information to confirm compatibility for your specific needs.

- Fuel

- Oil and Grease

- Hydrocarbons

- Chemicals and Small Equipment

- Drive Through Ready

- Durable

- Low Profile

- Materials Quickly Moved on and off

- Resists a Broad Spectrum of Chemicals

- Rolls up for Easy Transportation

- Built to your Size Requirements

- Cost-Effective Containment Solutions

- Rapid Response to Leaks and Spills

- Optional abrasion pads, liners, drive tracks and self-bailers available

- Job site Secondary Containment

- Frac Tank Containment

- Car/Vehicle Wash Down

- Leaking Equipment

- Fueling Trucks/Stations

- HAZMAT Spill Response

- Large Machinery

MINI BASINS

They are suitable for holding small tanks, equipment, cans and drums that may leak. The berm is also great for temporarily holding items that require containment. This Mini Berm is made of strong, flexible material, with sides held up by fiberglass rods. These features make the berm easy to deploy and roll up again into small size for storage. The mini berm is one of the best options for secondary containment or spill protection on a small scale with easy accessibility.

Containment Berm Fabrics and Compatibility

Most of our fabrics are compatible with the following liquids. Please contact our team with MSDS information to confirm compatibility for your specific needs.

- Fuel

- Oil and Grease

- Hydrocarbons

- Chemicals and Small Equipment

- Opens and Unrolls in Seconds

- Light Weight

- Easy to Transport

- Compact Storage

- High Resistance Fabrics

- Provides Quick Response During Emergencies

- Effectively Holds Tools and Equipment

- Oil Drum Containment

- Chemical Drum Containment

- Tank Containment

- Paint Can or Pail Containment

- Small Leak Containment

- Containment Trays

- Battery or Generator Containment

SPILL PALLETS

These units meet spill containment regulations for storage of hazardous materials and comply with both SPCC and EPA spill standards including EPA Container Storage Regulation 40 CFR 264.175 and the Spill Prevention, Control and Countermeasure Act (SPCC) 40 CFR 112

Spill Pallet Chemical Compatibility

Most of our fabrics are compatible with the following liquids. Please contact our team with MSDS information to confirm compatibility for your specific needs.

- Fuel

- Oil and Grease

- Chemicals including acids and corrosives

- High load capacities

- Highly Chemically resistant polyethylene (LLDPE) construction

- Reinforced through design for industrial strength

- Other styles available

- Accessories such as loading ramps or pullover covers available

- Oil Drum Containment

- Chemical Drum Containment

- Tank Containment

- Paint Can or Pail Containment

- Small Leak Containment

- Battery or Generator Containment

FLOATING CONTAINMENT MAT

Floating Containment Mats are also useful in diffusing water pressure from discharges into water bodies where the hydraulic force of the incoming water flushes turbidity from a silty bottom.

Standard Floating Containment mats feature a 22 oz. PVC material that is equipped to handle contact with water, paint and other debris and options are available for additional protection. Silt mats can be made in sizes as small as 10′ x 10′ up to 15′ x 30′ and larger sizes or custom dimensions can be made as requested.

- Drive Through Ready

- Durable

- Low Profile

- Materials Quickly Moved on and off

- Resists a Broad Spectrum of Chemicals

- Rolls up for Easy Transportation

- Built to your Size Requirements

- Cost-Effective Containment Solutions

- Rapid Response to Leaks and Spills

- Optional abrasion pads, liners, drive tracks and self-bailers available

- Job site Secondary Containment

- Frac Tank Containment

- Car/Vehicle Wash Down

- Leaking Equipment

- Fueling Trucks/Stations

- HAZMAT Spill Response

- Large Machinery