BAFFLES

GEI Works’ baffle curtain is a specialized structure used in wastewater treatment systems to control the flow of water and separate different zones within a treatment process. It is typically made of durable coated or laminated reinforced industrial materials with higher chemical, UV and marine growth inhibiting properties, and are designed to withstand the harsh conditions of wastewater environments. This allows for a larger active area and improved efficiency. The use of these reduces the Total Suspended Solids (TSS), improves overall water quality and assists industry comply with state and federal regulations for discharge and treatment of industrial wastewater.

Our technical advisors can help determine which materials and configuration may assist you in project goals as needed. Additionally, GEI Works can manufacture baffle curtain systems to meet your engineer’s specifications.

- Reinforced Flow Through Windows

- Chemically Compatible Material Options

- Hook and Loop Options

- Stainless Steel Options

- Dual Tension Cables Available

- ASTM End Connectors

- Wastewater Industry

- Treatment Facilities

- Power Plants

- Municipal Facilities

- Tank Storage

- Environmental Industry

- Mining

- Raw or Potable Water

- Acids or Caustics

- Hydrocarbons

- Process Water

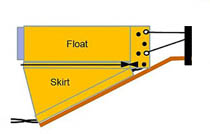

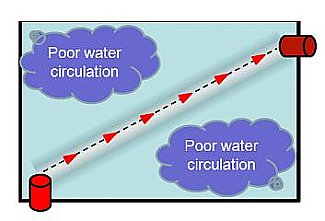

WATER BAFFLE

The Water Baffle is used in industrial and municipal waste water treatment process plants to control and improve water quality in a treatment plant. Typically constructed from impermeable PVC, these barriers have worked to improve BOD, lower TSS (total suspended solids), and lower thermal control exchange in water treatment plants.

Click to learn more about our Water Baffle Solutions.