Dewatering

Optimize your water management with GEI Works’ Filtration Solutions. Our range of products, including Dewatering Bags, Dewatering Socks, Pipe Socks, Dewatering Tubes, Sludge Tubes, Stormwater BMP, and Erosion Control Products, are designed to effectively filter and manage sediment and contaminants. Ensure compliance and environmental protection with our high-quality, durable filtration systems for industrial, construction, and stormwater applications.

Sed porttitor lectus nibh. Vivamus magna justo, lacinia eget consectetur sed, convallis.

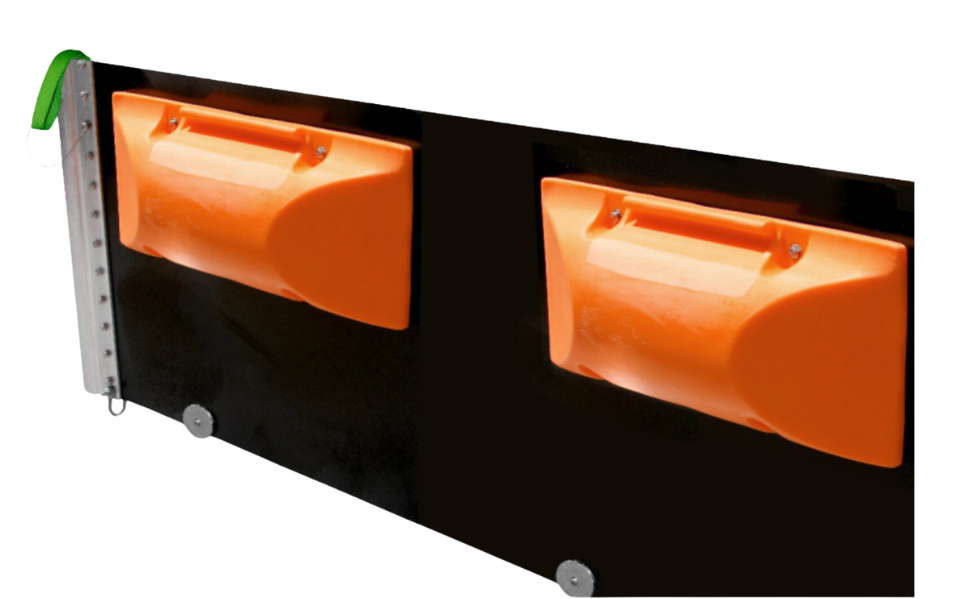

Dewatering Bags

Dewatering Bags, also known as sediment filter bags or silt bags, are an easy and economical option for any site looking to remove sediment or silt from their discharge. Each Standard Sediment Bag is constructed from a robust geotextile filter fabric to catch and contain sediment as muddy water is pumped from your site. These filtering bags are made from a non-woven geotextile fabric that is needle-punched to allow water to flow back out while retaining fine soils and particles. Its high filtering qualities make it ideal for pumping trenches, construction sites, dredging areas, ponds, lakes and for dewatering in municipalities or plants. (Available in Standard and Heavy Duty options)

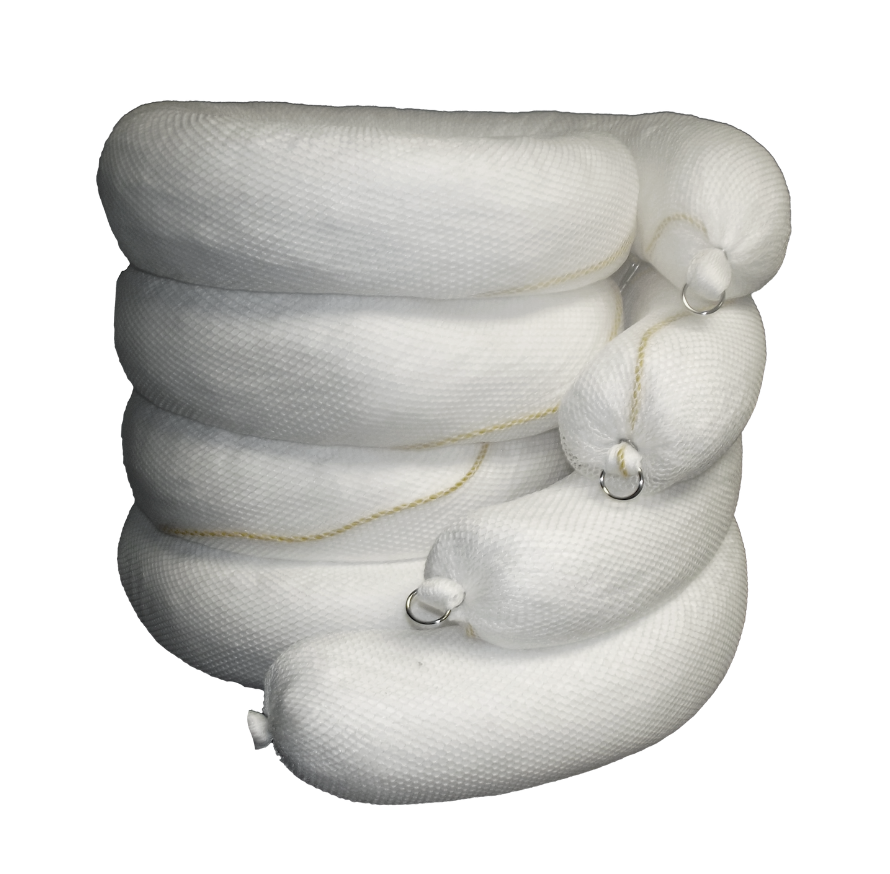

Dewatering Socks

GEI Works’ manufactured Dewatering Socks helps you control and contain sediment during dewatering, sump pump-outs or other containment products. Dewatering filter socks are one of the easiest ways to filter water runoff as it leaves your site. Designed to attach directly to the end of vertical dewatering pipes or hoses, these filter socks contain sediment, debris, and other pollutants as the water discharges from your site. Pipe socks are DOT compliant.

Their components meet or exceed minimum DOT Erosion and State NPDES Sediment Control requirements as outlined in 40 CFR 122.26. These pipe socks help keep runoff clean and keep your site in compliance with local and federal stormwater regulations.

Size: 4″x60″

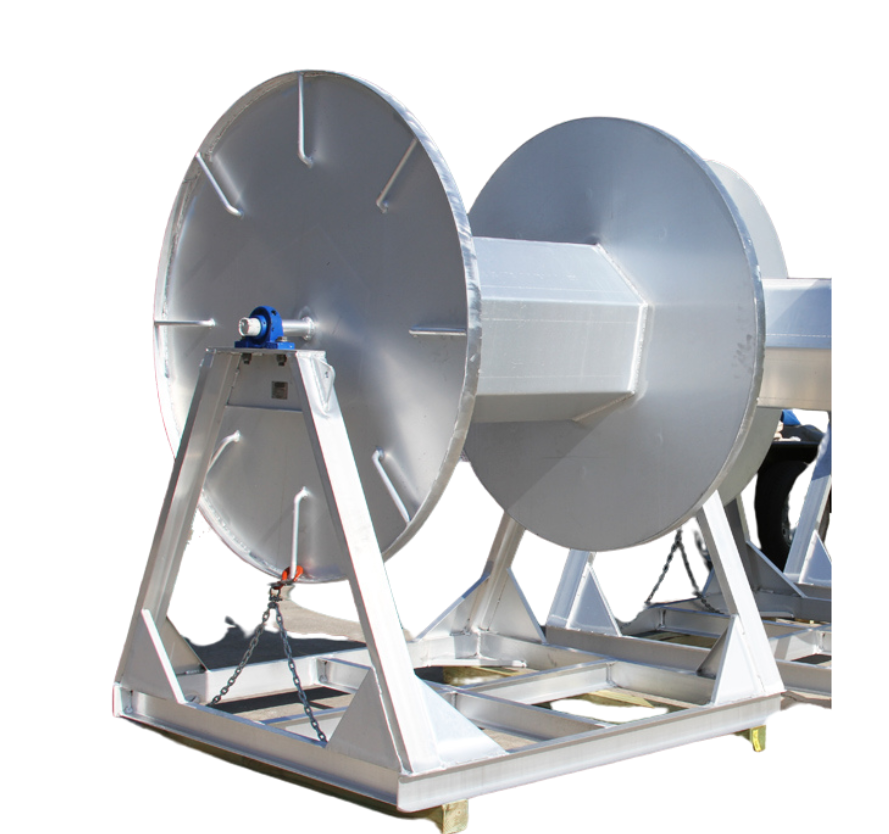

Dewatering Tubes

Dewatering Tubes or Geotubes, are a reliable and cost-effective solution to manage water on your construction site, industrial project, or environmental remediation site for volumes that are measured in cubic feet of sediment. GEI Works’ high-quality dewatering tubes are designed to handle large volumes of water. They are the ultimate tool for effective sediment and water separation, ensuring clean and clear results. These close-ended tubes contain filling ports evenly spaced at intervals along the length to allow for even hydraulic filling of a slurry of sand and water.