PILLOW TANKS

Standard Fittings include: (2) 2” Bulkhead Flanges, (2) 2” Male NPT Nipples, and (2) 2” Caps

- Potable Water Storage: FDA and NSF 61 Approved Fabrics

- Capacities From 25 to 25,000 Gallons

- Folds Flat for shipping

- Easy installation

- Optional Fittings Available

- Custom Designs & Sizing Available

- Accessories: Ground Cloth, Tank Covers, and Liners

- Disaster Relief Efforts

- Drinking Water Storage

- Construction Site Storage

- Facility Storage

- Rainwater Collection

- Military Operations

- Void Fill

ONION TANKS

The materials utilized for Onion Tanks can be selected to be compatible with the type of liquid you are storing in your tank. While most folding tanks are used for the storage of water, these options can vary from drinking water compatible options to standard gray water storage. Drinking Water fabrics will meet NSF 61 and FDA requirements, while gray water tanks may offer fabrics with added chemical resistance.

- Folded Design for Easy Transportation

- Fits in Vehicles and Fire Trucks

- Self supporting and self rising

- Unfolds in Minutes

- Open Top for Easy Access

- Covers, drains, ball valves and compression pads available

- Temporary Water Storage

- Product Testing

- Fish Ponds

- Secondary Containment

- Industrial Water Storage

- Frac Water Storage

- Decon Pools

- Fire Fighting Efforts

- Remote Location Water Storage

- Irrigation Water Storage

FRAME TANKS

The interior liner on each Folding Frame Tank is manufactured with a fabric option that is compatible with the type of liquid you are storing in your tank. While most folding tanks are used for the storage of water, these options can vary from drinking water compatible options to standard gray water storage. Drinking Water fabrics will meet NSF 61 and FDA requirements, while gray water tanks may offer fabrics with added chemical resistance.

- Folded Design for Easy Transportation

- Fits in Vehicles and Fire Trucks

- Reliable Interior Liner

- Unfolds in Minutes

- Open Top for Easy Access

- Filtration

- Dewatering

- Dredging

- Sediment Removal

- Bank Reinforcement

- Contaminated Sediment Removal

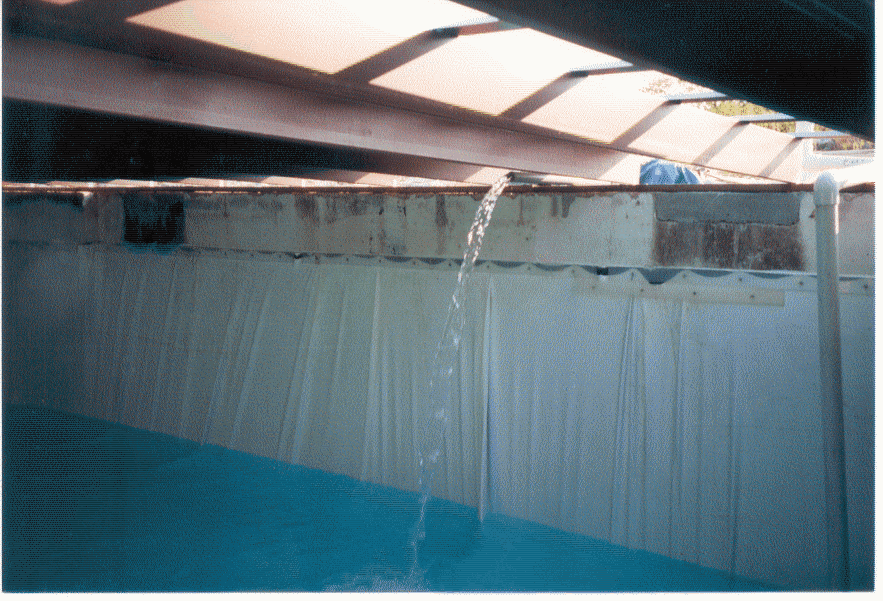

CORRUGATED TANK STORAGE

Fire Suppression Tanks:

Bolt-together tanks are common for NFPA22 rated tanks for fire suppression in particular. When sizing tanks for fire suppression water storage the ‘usable’ volume is the metric to size the tank against. Nominal capacity is a general guide and with the type and location of requisite fittings, there is a reduction in available volume. Please provide the usable volume required by your Authority Having Jurisdiction (AHJ).

Dual Use Tanks:

Our customers regularly size their tanks for additional storage capacity over and above minimum requirements. For example, if a tank requires 45,000 gallons of usable water storage, a tank may be selected for an additional 25,000 gallons of water for use in Irrigation.

See our Flyer which covers an infographic on Dual Use Tanks for more information.

- High-quality Corrugated steel panels

- Engineering Services

- Easy Installation

- Efficient Shipping

- Flexible Sizing Options

- Customizable

- Cost Effective Long-term, high-volume storage

- Irrigation, livestock, and crop protection

- Bulk process water

- NFPA 22 compliant Fire Suppression Storage

- Rainwater Harvesting

- Firefighting Reserve

- Rural Drinking Water Reserves

- Stormwater Management

CISTERN LINERS

GEI Works also offers high-performance poly-urea waterproofing coating of new or reconditioned tanks. Poly-urea Coatings are one of the most cost-effective ways to control leaks, prevent corrosion, and extend the lifespan of your rainwater collection tank. Poly-urea spray liners have been used on old leaking tanks to provide a new impermeable layer, as well as on new cistern tanks to provide corrosion, rust or leak protection for the duration of their use. These spray liners can salvage existing welded steel, grain bin, cistern or corrugated tanks, saving demolition and replacement costs.

- Potable Water Storage: FDA and NSF 61 Approved Fabrics

- Custom built to customer dimensions

- Folds Flat for shipping

- Easy installation

- Optional battening kits available

Poly-Urea Coatings

- Prevents Rust / Corrosion

- Excellent for repair – seamlessly patches holes in tanks

- Chemical, abrasion and UV resistant

- Ecologically friendly – low VOC (meets CA VOC limits)

- 75+ year lfe expectancy

- Economical Protection of Investment

- Can eliminate Demolition and replacement tank costs

- Suitable for potable water or chemical environments

- Expands 6000% on application forming high performing bonds

- Drinking Water Storage

- Industrial or Irrigation Water Storage

- Tank refurbishment

- Rainwater Collection